‘22+

Polaris RZR PRO R

FDM Install Guide

Justin Shriver

Updated on August 1, 2024

Contents

Supported Models:

2022+ PRO R and PRO R 4

The vehicle shown in this document is a modified 2022 Polaris RZR Pro R. Your vehicle could have parts that may or may not be present in the pictures. The images are meant to be a reference. If you have any questions regarding your installation, please contact T1 Race Development at support@injectordynamics.com

Item List

|

22+ PRO R FDM Contents |

||

|

Item # |

Description |

Qty |

|

1 |

Polaris RZR Pro R Fuel Rail |

1 |

|

2 |

Pressure Regulator Assembly |

1 |

|

3 |

06 ORB to 06 ORB Coupler |

1 |

|

4 |

04 AN 90° Bulkhead Fitting |

1 |

|

5 |

04 AN Bulkhead Nut |

1 |

|

6 |

04 Stat O Seal Washer |

1 |

|

7 |

7/16″ Stainless Steel Washer |

1 |

|

8 |

FDM Assembly |

1 |

|

9 |

Tube Mount |

1 |

|

10 |

M6 Hardware |

4 |

|

11 |

06 AN E85 Rated Hose (73″), 90° and Straight Crimp Ends |

1 |

|

12 |

06 AN E85 Rated Hose (43″), 90° and Straight Crimp Ends |

1 |

|

13 |

06 AN E85 Rated Hose (56″), 90° and 90° Crimp Ends |

1 |

|

14 |

04 AN E85 Rated Hose (73″), 90° and Straight Crimp Ends |

1 |

|

15 |

3/8″ Female EFI to 06AN Male |

1 |

|

16 |

06 ORB Male to 06 AN Male |

5 |

|

17 |

06 ORB Male to 04 AN Male |

1 |

|

18 |

Wire Harness |

1 |

|

19 |

Fuse Holder Assembly |

1 |

|

20 |

Ring Terminal |

2 |

|

21 |

Metal Butt Splice |

2 |

|

22 |

Insulated Butt Splice |

1 |

|

23 |

Heat Shrink |

2 |

|

24 |

11″ Cable Ties |

10 |

|

25 |

3″ Miniature Cable Ties |

4 |

Fuel Rail + Regulator Kit

Removing Fuel Pump Module

Accessing the Fuel Pump (2 seat Model)

- Remove both seats and lower mounting bolts for the harnesses.

- Follow the manufacturer’s instructions to gain access to the fuel pump module.

- Remove center console storage compartment.

- Remove the upper and lower firewall panels.

- Remove both left and right center console panels.

- Remove the rear portion of the seat bracket assembly.

- Remove hardware from the passenger side rocker panel.

- Remove the panel that covers the fuel tank.

- Disconnect the power connector and crank the engine to bleed fuel pressure. Disconnect the battery once the pressure has bled.

- Disconnect the fuel line from the pump module. There will still be some fuel left in the fuel line.

- Remove the fuel pump ring and lift the fuel pump module out of the tank (drain as much fuel back into the tank as possible).

Accessing the Fuel Pump (4 seat Model)

- Remove both seats backs and flip the bottom cushions forward.

- Follow the manufacturer’s instructions to access the fuel pump.

- Remove both firewall panels.

- Remove both fabric corner panels.

- Remove the lap belt hardware.

- Remove panel that covers the fuel tank.

- Disconnect the power connector and crank the engine to bleed fuel pressure. Disconnect the battery once the pressure has bled.

- Disconnect the fuel line from the pump module. There will still be some fuel left in the fuel line.

- Remove the fuel pump ring and lift the fuel pump module out of the tank (drain as much fuel back into the tank as possible).

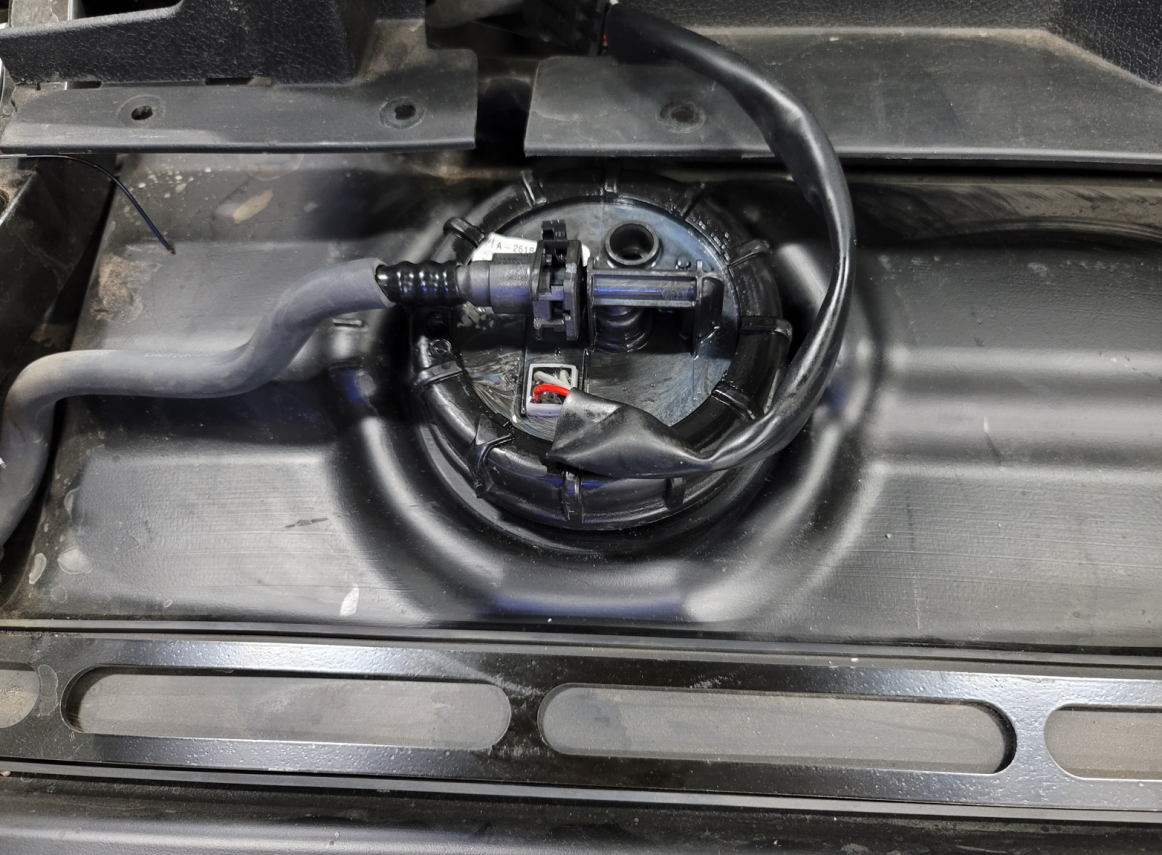

Figure 1: OEM reference.

Modify the Fuel Pump Module for Return Line

- Place the 7/16” washer on the underside of the Top Hat and using a marker place a mark in the center of the washer. Use figure 2 as a reference for the return line location.

Figure 2:Return Line placement reference

- Start by drilling a 1/8” pilot hole on the mark that was made in the last step.

- From the top side of the top hat, drill a 7/16” hole. A Unibit is recommended but it is also possible to start with a smaller drill bit and step up to a 7/16” bit.

- Install the -4 bulkhead fitting using the stat-o-seal on the top of the top hat and the 7/16” washer on the bottom side. Use figure 3 as a reference for the orientation of the bulkhead fitting.

Figure 3: Return line reference.

- Clearance between the return line fitting and body panel are extremely tight. In order to help prevent the chance of rubbing, it is recommended that are portion of the body panel is removed from the underside. Use

figure 4 and 5 for reference.

Figure 4 : Body panel reference (Before)

Figure 5 : Body panel reference (After)

- Reinstall the fuel pump module into the fuel tank.

- Install the 3/8” EFI adapter onto the outlet of the OEM fuel pump. Use figure 6 as a reference for all connections. (Style of adapter may differ from image).

Figure 6: Fitting Reference

Fuel Rail, Injector, and Regulator Install

- Remove the engine cover to gain access to the top of the engine.

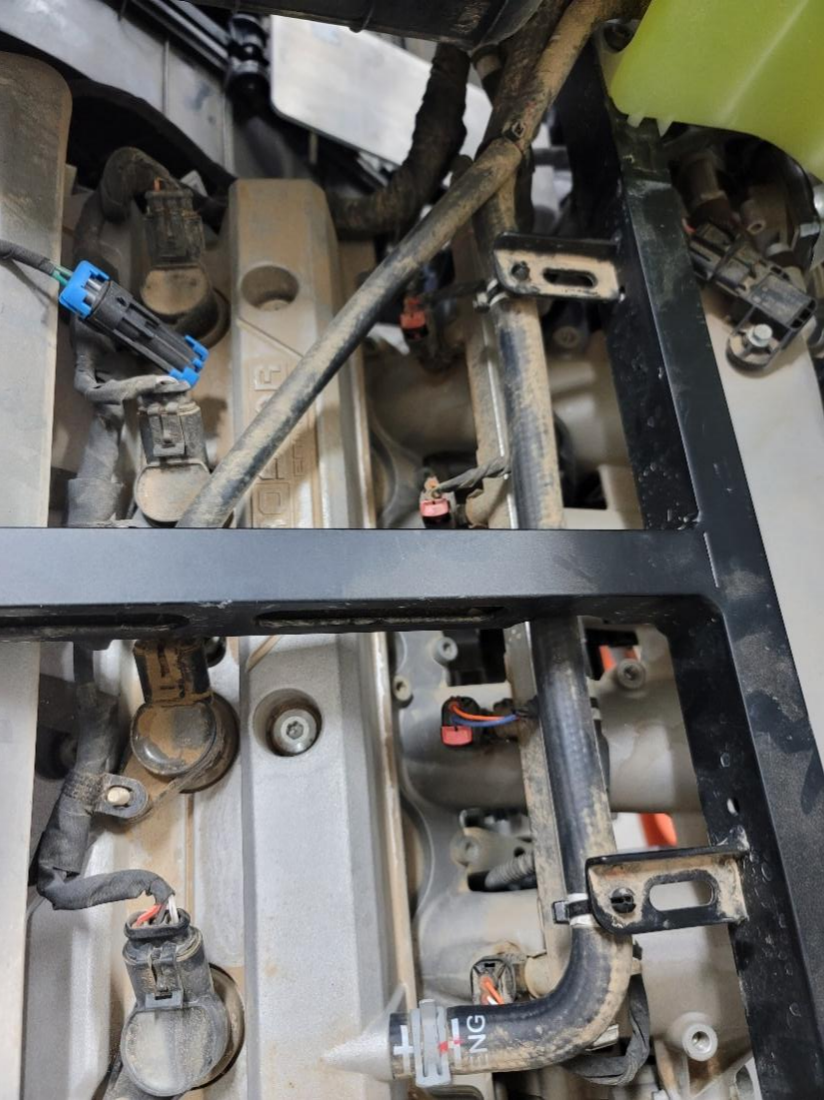

Figure 7: OEM Fuel Rail Reference

- Disconnect injector electrical connectors.

- Disconnect the fuel line from the rail. There will be fuel left in the fuel line. Remove from vehicle.

- Remove the (4) clips retaining the wire harness and (4) bolts to uninstall the fuel rail.

- Outside the vehicle, install the supplied fittings into the rail and regulator.

- Install the -6 ORB to -6 AN fitting on the inlet of the rail towards the front of the car.

- Install the -6 ORB swivel fitting on the outlet port of the rail. The non-adjustable side of the swivel fitting needs to be installed onto the rail.

- Install the -6 ORB to -6 AN fitting into the bottom of the regulator housing.

- Thread on the regulator housing to the swivel fitting until the threads bottom out, then back out one turn. Do not tighten the lock nut.

- Install the ID injectors into the fuel rail. (Apply some grease on all O-rings).

- Install fuel rail and injectors onto the manifold ensuring all injectors are properly seated

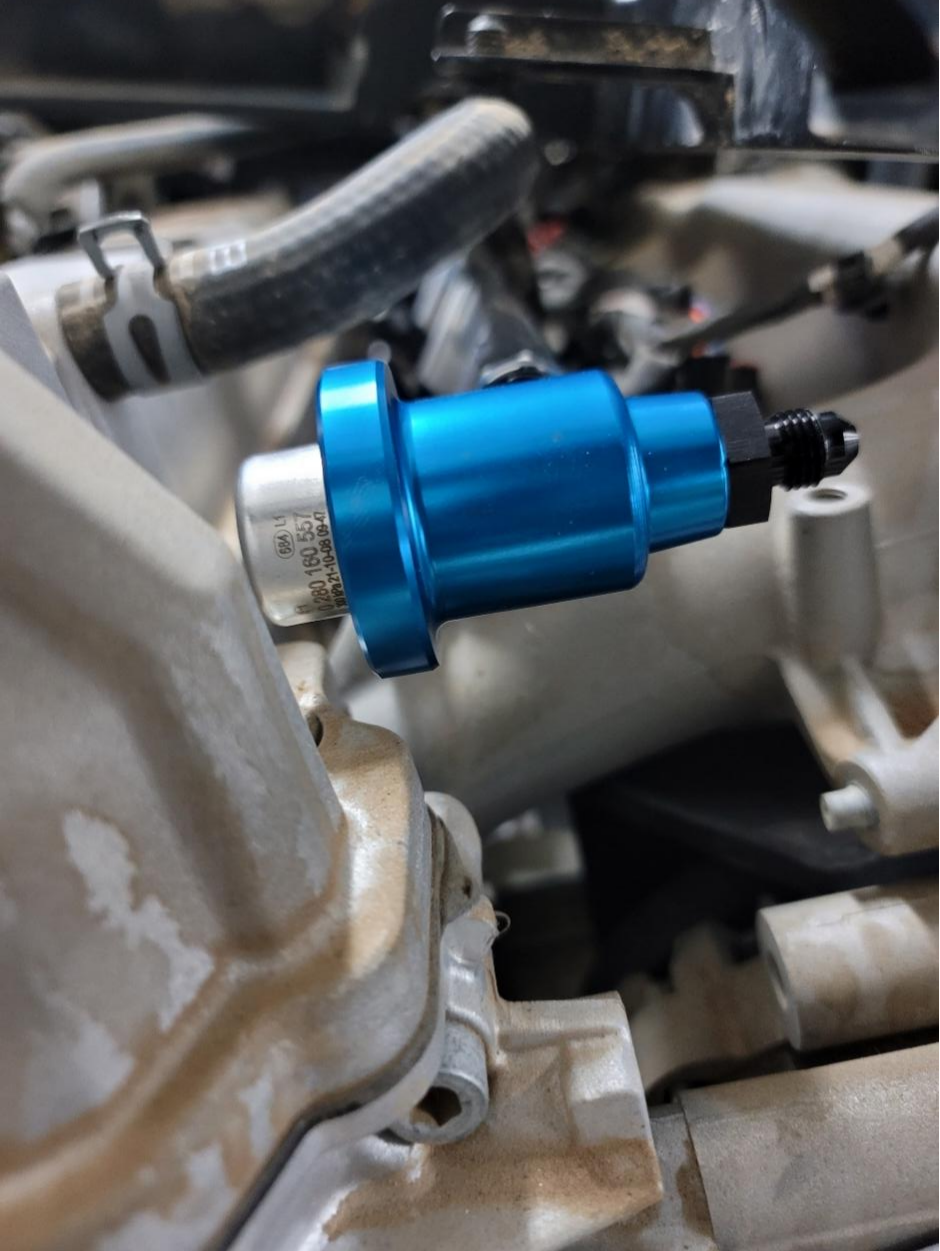

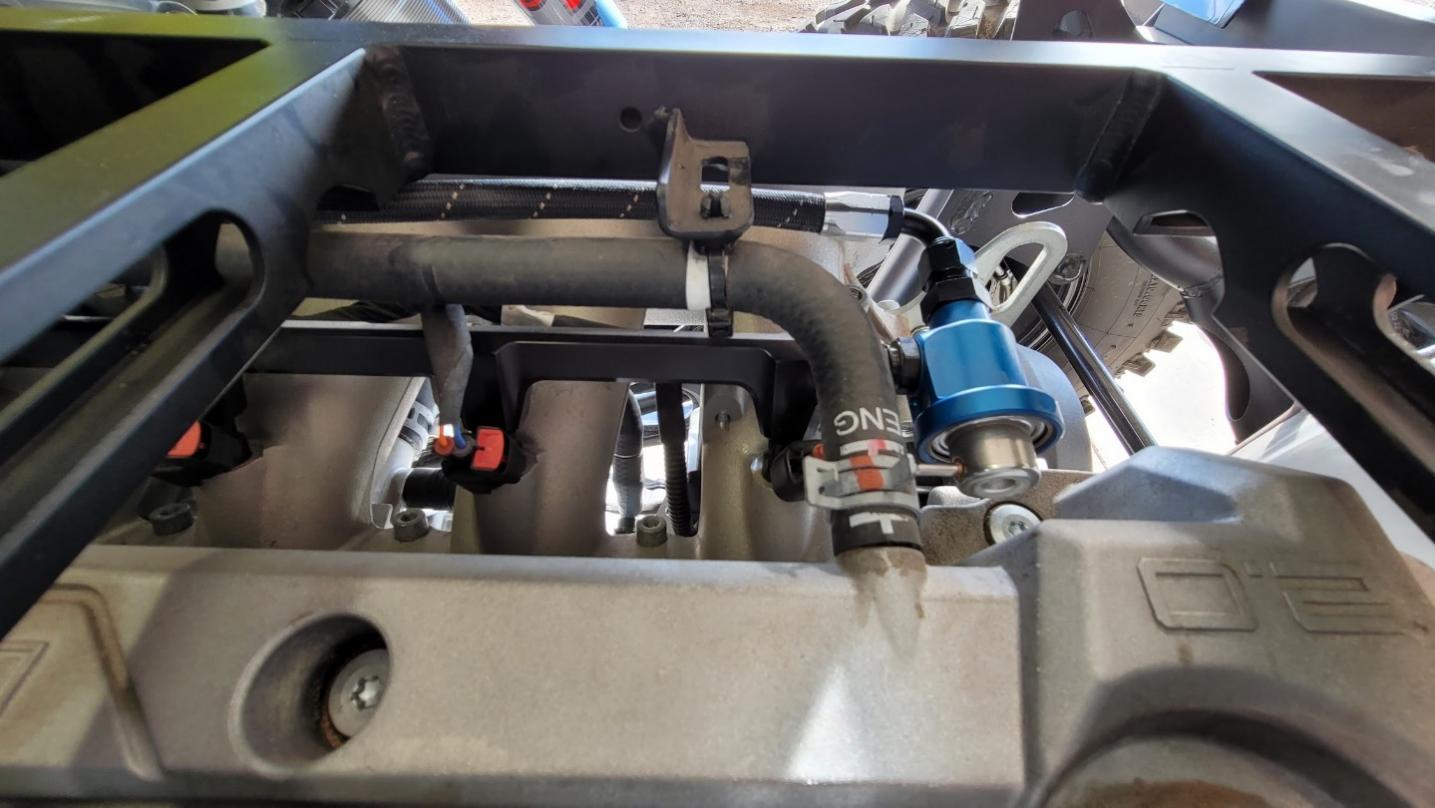

(Take care, not to over tighten bolts). - Orientate the fuel pressure regulator as seen in figure 8.

Figure 8: ID Fuel Regulator Reference

Installing the FDM

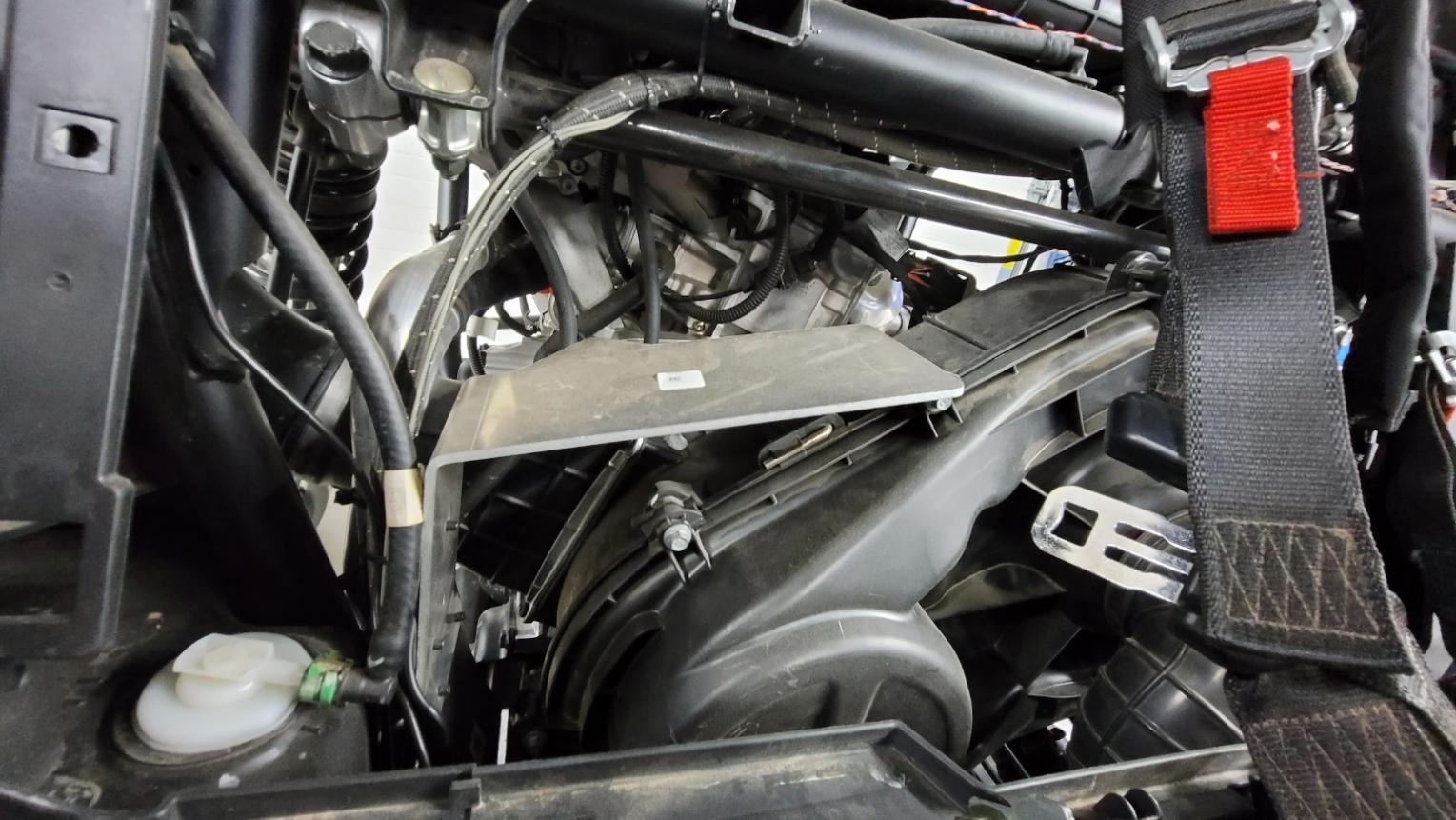

- Use figure 9 below as a guide for the intended mounting location.

Figure 9: Mounting Location

- Remove the driver side rocker panel

- Remove the driver side rear fender

- Remove the corner firewall panel behind the seat. This panel will need to be modified to mount the FDM.

- Measure down from the center of the top hole shown in figure 10, marking at 1.5” and 4.375”. Draw a straight line around the corner of the plastic all the way to the edge of the panel shown in figure 10 and 11.

Cut along the marked line.

- Measure down from the center of the top hole shown in figure 10, marking at 1.5” and 4.375”. Draw a straight line around the corner of the plastic all the way to the edge of the panel shown in figure 10 and 11.

Figure 10 – 11: Panel Modification Reference

- Reinstall the corner firewall panel. Check fitment with the FDM, trim if needed.

- Mount the FDM using the supplied clamp and hardware directly below the upper door hinge. Do not fully tighten bolts.

- Hold the rear fender in place and position the FDM so that it is not contacting the fender. Tighten FDM clamp hardware.

Mounting and Hose Routing

- Install the provided ORB to AN adapters in the FDM using figure 11 below. NOTE: When installing adapters and hoses, limit the rotation of the top cap while tightening. Also ensure that the hoses are not rubbing on

adjacent fittings. Secure all hoses with supplied cable ties.- Port 1 – 6 AN to 6 ORB. FDM outlet to fuel rail.

- Port 2 – 6 AN to 6 ORB. Feed from OE pump.

- Port 3 – 4 AN to 6 ORB. Return to OE fuel tank.

- Port 4 – 6 AN to 6 ORB. Return from regulator.

Figure 11: FDM Port Reference

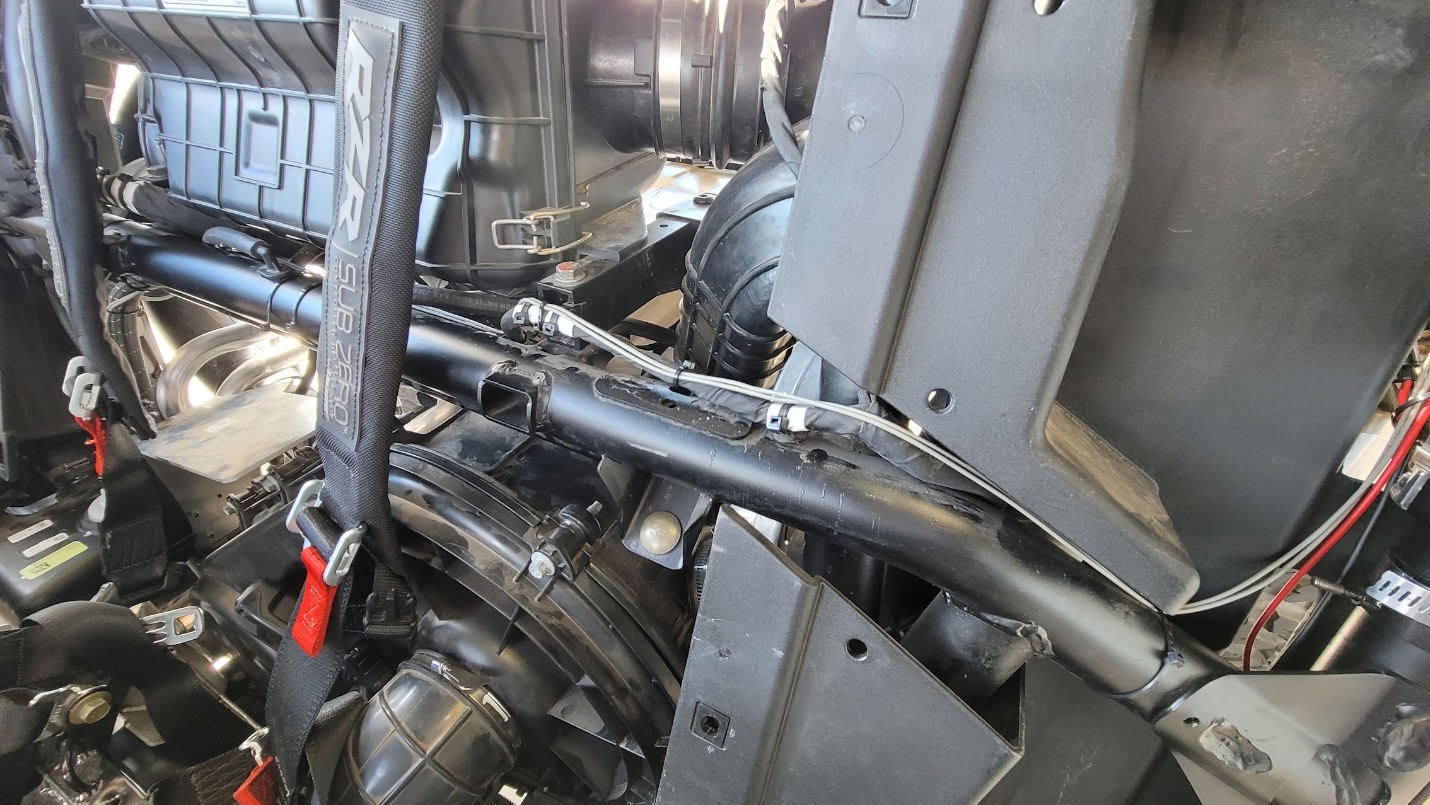

- All four hoses will be routed through the same location from the FDM. Use figures 12-14 as a reference.

Figure 12-14: Hose Routing Reference

- Starting with the longest (73”) 6 AN hose, route the hose from the FDM to the EFI adapter on the OEM fuel pump. Connect the straight fitting to the EFI adapter and the 90° fitting to port 2 on the FDM.

- Route the 4 AN hose along the 6 AN hose from the FDM to the return fitting on the OEM fuel pump. Connect the straight fitting to the return fitting and the 90° fitting to port 3 on the FDM. Use figure 15 for the routing of the two hoses to the OEM pump.

Figure 15: Hose Routing Reference

- Route the 43” 6 AN hose from the FDM to the fuel rail. Connect the 90° fitting to port 1 on the FDM and the straight fitting to the fuel rail.

- Route the remaining 6 AN hose from the pressure regulator to port 4 on the FDM. Use figures 16-17 as a reference for the fuel rail feed and return line from the regulator.

Figure 16: Hose Routing Reference

Figure 17: Hose Routing Reference

FDM Wiring

- Run the electrical harness through the section of the corner firewall that was modified previously.

Route the red and black wires to the battery and the two gray wires to the OEM fuel pump. Cutt off excess wire. Use figure 18 as reference.

Figure 18: Electrical Routing Reference

- Cut the fuse wire loop to your desired leg lengths. Using the blue insulated butt splice, connect the red wire from the FDM to one of the legs on the fuse holder. Crimp one of the supplied ring terminals to the other leg of the fuse holder.

- Crimp the other ring terminal to the black wire from the FDM.

- Using the metal butt splices, splice the gray wires from the FDM to the OEM pump power (red/black) wire and ground (black) wire. It does not matter which gray wire is hooked to the OE pump power and ground.

- Connect the red and black wires from the FDM to the battery.

- Secure all wires with supplies cable ties.

Fill FDM and Check for Leaks

- Reconnect the battery.

- With the electrical connector to the FDM unplugged, prime the fuel system multiple times to fill the FDM.

- Check for leaks.

- Connect the FDM electrical connector and prime the system. Listen for the FDM pump and look for the blue LED on the underside of the FDM.

- Check for leaks.

Flash ECU

- Generate ECU data by using the online generator located on the Injector Dynamics website at http://injectordynamics.com/utv/ and follow the directions to make the changes in the calibration.

- Once the ECU flash is complete, start the vehicle ensuring that there are no leaks in the fuel system

(Always have a fire extinguisher close by).

Reinstall All Remaining Parts

- Once you have ensured there are no leaks, reinstall all body panels and seats in the reverse order of removal.